One of the least known engine components of your car is the rod bearing. If there’s a problem with the rod bearing, you need to repair or replace it, or your engine may not even work. This article describes what a rod bearing is, how to replace it, and its cost.

In a typical car engine, the rod bearing is just a plain bearing. It is not like a ball bearing with small balls. The rod bearing holds the spinning shaft in a place where support is needed. This support enables the rod to remain straight during the combustion cycle. The term rod bearing can also refer to the connecting rod bearing.

It costs about $2,000 to $3,000 to replace rod bearings. This price already includes parts and labor. Typically, repairing connecting rod bearings will include flushing out the engine and cooler lines, replacing the gaskets, seals, and cylinder head bolts.

Read on to learn more about what rod bearings are, what causes rod bearing problems, how to fix these problems, and the cost of repairing or replacing them.

What Is a Rod Bearing?

In automotive technology, the rod bearing is just a plain bearing and not a ball bearing with small balls. A rod bearing holds and supports the spinning shaft in its part where it needs support.

This is done so that the rod will remain straight during the combustion cycle. This name can also refer to the connecting rod bearing because it is directly attached to the connecting rod. These are engine parts that are just some of the many components or parts of an engine. These parts are all enclosed inside the engine block of the car.

If a mechanic says that your car engine needs a rod bearing replacement, you can expect to spend $2,000 to $3,000 for parts and labor. The work will usually involve the engine’s flushing and cooler lines and then replacing the seals, gaskets, cylinder head bolts, and connecting rod bearings.

But before you drive your car into the repair shop, you should clarify first if you really have bad or worn-out rod bearings.

If Rod Bearings Go Bad, What Happens?

When the rod bearings are wearing out, there will be too much clearance between them and the connecting rods they are supporting. This will cause the big ends of the rods to beat against the spinning crankshaft. You will then hear rod knocks on your engine. So, these knocking sounds are a major symptom of bad engine bearings.

In many cases, an engine with a bad rod bearing will trigger the ‘check engine oil’ light in your car’s dashboard. And this light may or may not go out after the engine runs for a couple of minutes, depending on the severity of the bearing problem.

Spun Rod Bearing

One major problem that involves failing rod bearings that you need to avoid at all costs is what car mechanics call ‘Spun Rod Bearing.’

When a rod bearing is spun, it means that the lubrication system of the rod bearing has failed. That means the rod bearing does not get any lubricant while the shaft is constantly spinning inside this dry bearing.

The shaft heats up very quickly and expands considerably. At its expanded state, the shaft grabs the rod bearing and detaches it from its bolts. At this point, the rod bearing is practically welded to the rod and is now spinning with it.

If you keep on driving your car with a spun rod for several miles, the rod-end bearing will heat up considerably. This will result in the throwing off of the piston rod. Then, your car engine will suffer damage that could be beyond repair.

Are There Different Rod Bearings?

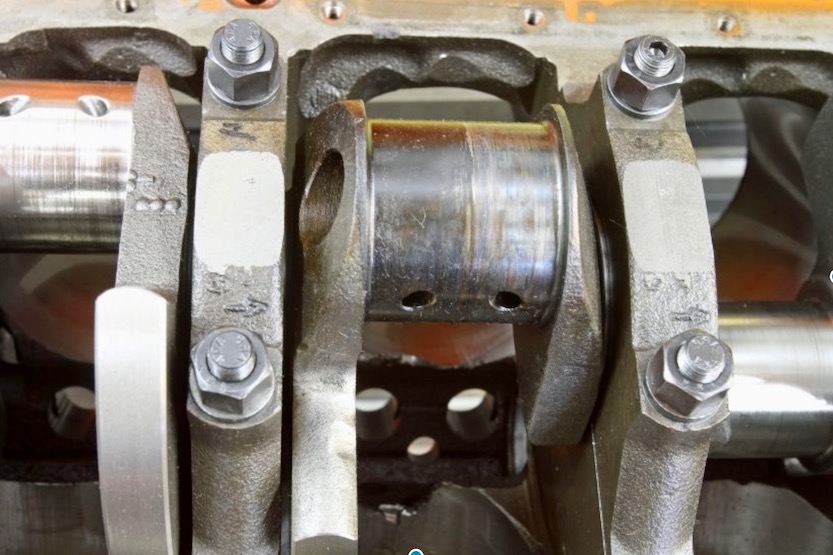

A rod bearing has two circular metal bands, one at the top and another at the bottom. It is simply two bands of smooth metal in the form of a circle when assembled. The top metal band is semi-circular in shape, so is the bottom band.

For instance, in the driveshaft rod bearing, the top half is mounted to the car’s undercarriage. The bottom half is bolted to the top half once the driveshaft is put in place.

There’s a pinhole at the top half band. This pinhole allows the lubricant to enter its insides. This way, the driveshaft can spin within the rod bearing without producing excessive heat.

Different Names of Rod Bearing

There is only one overall design of rod bearings. But you can refer to it using different names, such as connecting rod bearing, rod-end bearing, Heim joint (in the U.S.A.), and rose joint (in the U.K.). There may be variations in the basic design, but the basic form and function are the same in most cases.

These bearings connect the piston rods to the bearing journal. This bearing journal is the section of the piston rods that get in contact and turns the driveshaft. Replacing the rod bearings is a standard step in engine repair or engine rebuilding.

The rod bearings of an engine are different from their main bearings. Rod and main bearing torque specs are not the same. You can find the main bearings between the crankshaft and the engine block, while rod bearings are between the rod and the crankshaft.

So the term ‘rod bearing’ is short for a ‘connecting rod bearing.’ A connecting rod bearing provides motion of the crankpin within the connecting rod. This rotation transmits cycling loads applied to the piston. Connecting rod bearings are on the big end of the connecting rod.

Why Be Concerned About Rod Bearing Problems?

If you fail to recognize and fix the problems caused by rod bearings, it may lead to serious engine failure. This is why car manufacturers have made adjustments to their engine designs by developing sealed transmissions.

Modern engine design enables the driveshaft to spin while being submerged in transmission fluid. This makes rod bearing failure very rare in modern vehicles. However, there is no longer a need for a reservoir for the transmission fluid with sealed transmission designs.

This reservoir is handy because it is the first engine component that provides the early warning sign for transmission fluid leaks. So, when you hear a persistent ticking inside the engine that increases if you rev it at high speeds, you should still suspect a bearing problem.

Worn Out Rod Bearings

If you hear a rod knock on your engine, it could be that the rod bearings are wearing out, or your oil pressure is shallow. Changing the oil filter and pouring in new engine oil may cause this noise to stop. However, after changing the oil and you notice that the noise is still getting worse, your rod bearings could have been damaged and is now beyond repair.

If you hear rod bearing knocks, you only have at most 30 seconds before the engine fully freezes. The moment the oil film cannot lubricate and support the rod over the crank, there will be a crank to rod contact in that instant. The rod bearing will only last that long at the speed by which the engine is running.

Spun Rod Bearing

A spun rod bearing is another problem you should avoid. This occurs when the rod bearings seize themselves around the crankshaft journal. The bearings will tear up the big end bores in their rods.

They will damage the rod journal. There are times when they may break the connecting rod. But the engine can last longer if its bearings are spun. The most it can reach is about 50 miles.

Symptoms of Rod Bearing Problems

You need to know the symptoms of rod bearing problems early on. This will help you avert any situation that could damage your car engine beyond repair.

Here are some of the things you need to watch out for:

- Loss of oil pressure

- Silver shavings in the oil

- Noise in the engine

- Copper sheen in the oil

- Transmission noise and worn out belts

Cause of Rod Bearing Problems

Rod bearing problems don’t just appear out of the blue. Several things cause them, and you should know the common causes so you can avoid them:

1. Abrasive Contaminants

Rod bearings can be damaged by all kinds of contaminants in the lubricant. These abrasive contaminants are usually introduced in the rod bearing lubrication system if they are not fully removed from the engine when it was overhauled.

These contaminants may come from deformed connecting rod bearing bores or a worn crankshaft. They may cause the uneven wearing of the rod bearings in their contact points in the connecting rods.

2. Collision of Different Parts

When the crankshaft journal collides with the bearings, you will hear knocking sounds coming from the engine. Ignoring these knocking sounds will only make the problem worse. More damage to the engine will result.

3. Spun Bearing

Spun bearing causes the rod bearing to jam up. This causes the clearance between the inner surface of the bearing and the connecting rod to increase. As a result, there will be excess play between these two connected parts, creating the knocking sound.

Other causes of spun bearing include the following:

- Loss of lubrication

- Excessive heat

- Lack of lubrication

- Contaminants in the lubricating fluid

- High operating loads

How to Fix or Replace Rod Bearings

The function of connecting rod bearings is to protect the connecting rods and the crankshaft from damage caused by friction. With the help of lubricating oil, they help reduce the friction and heat generated between these metal parts.

But over time, these rod bearings will also wear out. So, you must periodically check them to see if they are still in good condition. If you don’t check them regularly, you can face serious engine problems.

If you suspect that your car engine already has rod bearing problems, follow the below procedure to check or fix the issue:

1. Prepare the Tools and Materials

The materials and tools that you will need to fix the problem include the following:

- New engine oil

- Drip pan

- Wrench

- Oil pan gasket

- Gasket sealant

- Oil pan gasket

- New rod bearings (the size and part number for your car engine)

2. Buy the Right Bearing

If you know how to do it, disassemble the problematic rod bearing from its connecting rod. Bring it to the auto supply store and show it to the staff. Ask for the same bearing to ensure that it is the right one for your car engine.

3. Mark the Parts

You have to remove the bearing from the crankshaft assembly. There are many bolts and nuts that you need to unscrew to remove the problematic bearing. So that you won’t make any mistakes in the assembly, mark the parts as you disassemble them.

Place the disassembled parts in clean plastic containers. Use a labeling system to help you assemble them when you are ready to install the new rod bearing.

4. Remove the Old Bearing

Removing the old bearing may be a bit difficult. In some instances, these bearings slide off easily. But in many cases, you have to give it a slight tap before it lets go of its connection. Use a soft rubber mallet to tap and loosen it up. Tap its top edge and not its sides.

5. Clean the Parts

Clean every part that you have disassembled from the crankshaft. This will ensure that you will not introduce any contaminants that may cause rod bearing problems in the future. Use a degreaser or mineral spirits in cleaning these items.

6. Install the New Rod Bearing

Once all the disassembled parts are clean, start re-assemble them in reverse order as you have disassembled them. Put a film of engine oil in the new connecting rod bearing before putting it in place.

Cost to Replace Rod Bearings

The job of replacing rob bearings may not be for many people. If you are not confident about doing it yourself, you can always ask a professional car service center to do it. In that case, you can expect the cost of replacement to be anywhere between $2,000 and $3,000. That will include parts and labor.

If the mechanic says your engine is damaged severely by the rod bearing problem and you will need new pistons and connecting rods, as well as a new timing chain, camshaft bearings, and new crankshaft, you will be better off getting a new engine assembly.

But you only need to replace the broken rod bearings if they are the only problem and if there is no damage to the crankshaft and other parts of the engine.

Conclusion: Rod Bearing

In a typical car engine, the rod bearing is a plain bearing that holds the spinning shaft where it needs support. It is not like a ball bearing with small balls. By supporting the spinning shaft, this bearing enables the rod to remain straight during the combustion cycle. The term ‘rod bearing’ can also refer to ‘connecting rod bearing.’

The typical rod bearing replacement cost is about $2,000 to $3,000. This price already includes parts and labor. Repairing connecting rod bearings will include flushing out the engine and cooler lines, replacing the gaskets, seals, and cylinder head bolts.

What is a spun rod bearing? A spun rod bearing welds itself to the crankshaft and will spin in its housing. This means oil starvation and a shower of metal shavings flying through the oil system at best.

Related reading:

Metal Shavings in Oil – What Does This Mean?

What Happens When Cam Phasers Go Bad?

Tie Rod Replacement, Symptoms [Inner and Outer]

![Nissan Key Fob Battery Replacement – [How to Change It?] nissan key fob battery replacement](https://roadsumo.com/wp-content/uploads/2022/11/Nissan-key-fob-battery-replacement-150x150.jpg)

![Read more about the article Car Making a Creaking Noise When Driving Slow [7 Causes]](https://roadsumo.com/wp-content/uploads/2022/07/car-making-a-creaking-noise-when-driving-slow-300x200.jpeg)

![Read more about the article Car Idling Rough [Causes and How to Fix]](https://roadsumo.com/wp-content/uploads/2021/12/car-idling-rough-300x200.jpg)