If you upgrade your car’s lighting system with newer lights and newer electrical parts, you need to be sure that they will last. To help prolong the use of the lights, you can use bulb grease. What is bulb grease, and why is it important?

Bulb grease is dielectric grease that is usually made of silicone. It is used to prevent corrosion and rust and to improve the efficiency of electrical connections. You can use it on electrical connections, light bulbs, tail lights, floor lamps, batteries, headlights, and so forth.

Bulb grease is waterproof. It is made up of silicone and a thickener. The most common silicone oil used in the process is polydimethylsiloxane (PDMS), while the thickener is amorphous fumed silica.

Read on to learn more about bulb grease and how you can use it to protect your car’s electrical parts, its electrical wiring connections, and its lights.

What Is Bulb Grease?

Bulb grease is a shielding substance you can use to protect your car’s electrical connections, headlights, rear lights, and other electrical parts. You can also use it in the electrical sockets in your house.

Its substance is made of silicone dielectric, improving electrical connections’ efficiency and preventing corrosion and rust.

Manufacturers produce dielectric grease by mixing silicone oil and a thickener. Polydimethylsiloxane (PDMS) is present in the silicone material, and the thickener contains amorphous fumed silica.

If you use bulb grease in your next car lighting upgrade, it will save you money, time, and effort. Why? Your lighting connections and electrical parts will be resistant to moisture.

They will not develop corrosions and rusts. Repairs and replacements of these parts will be fewer. You can use it in any lighting installation or upgrade that has electrical connections and electrical parts.

This bulb grease can work as a seal or shield to anything applied to it. If you apply it on electrical connections continuously exposed to moisture, it will seal the connection/connectors not to get inside and corrode its electrical parts.

How to Apply Bulb Grease?

You can use bulb grease on electrical connections and electrical parts as a preventive measure against rust and corrosion. Bulb grease application is straightforward. Thus, you can do it regularly on all exposed car electrical connectors.

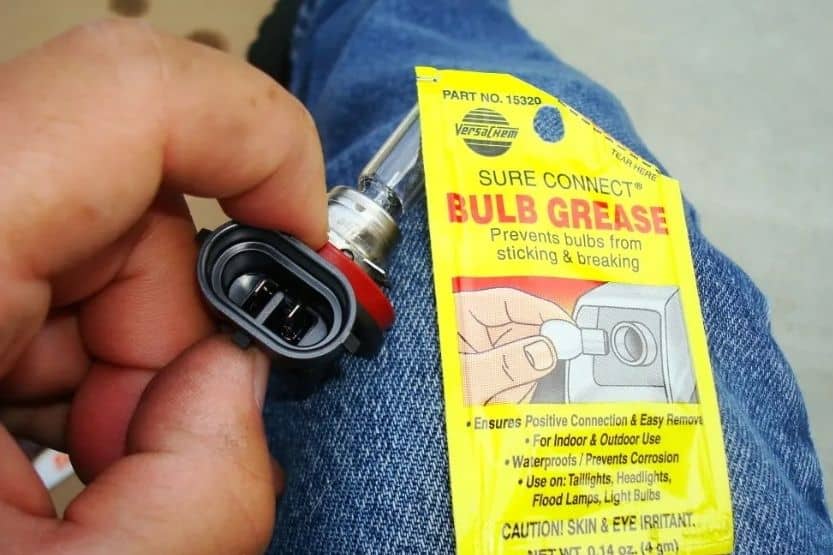

You should apply it to the bulbs, spark plug boots, hood electrical connections, and all other connectors prone to wetting and corrosion. You can buy bulb grease in a big tube or a small packet according to the sealing amount you need.

To apply bulb grease on any connector, follow these steps:

1. Remove the Electrical Part

The first step is to remove the bulb from the socket or unplug the connector or remove the electrical component you are working with. You should be careful in removing the electrical part so that it will not break. If it breaks, you have to replace it before making the reconnection.

2. Clean the Electrical Part

Clean the connector or electrical part:

- Mix baking soda and water and get a small wire brush.

- Dip the wire brush into the cleaning mixture of water and baking soda.

- Use the wire brush to clean the connector or the thread of the light bulb or its socket. Apply gentle pressure only.

- Continue cleaning until the connector or electrical part is completely clean.

3. Scrape Off Tough Dirt

- Get a pick tool or a small screwdriver.

- Scrape the caked and tough dirt from the light bulb‘s thread, socket, electrical part, or connector.

- You should be careful to scrape the dirt only.

4. Apply Bulb Grease

- Open the tube or the packet of bulb grease.

- Apply a small amount to the light bulb’s cleaned surfaces and socket or where the connectors meet.

- This dielectric grease coat will prevent corrosion and rust from forming on the bulb’s cleaned surface and the connector. It will also allow electricity to flow through it.

5. Reassemble the Connector

- Reassemble the connector or thread in the bulb to its socket or reconnect the electrical part carefully.

- If excess grease squeezes out of the connector or electrical part, wipe it off with a towel or a rag.

Why Use Bulb Grease?

One of the most common problems with light bulbs is that they are usually left to fend for themselves. If you don’t check it from time to time, it’s susceptible to corrosion. Then they stop working.

Why?

Rusts that formed in the sockets and the bulb threads prevent the flow of electricity.

You may not also unstick the bulb on its socket. When that happens, it will be tough to remove it from the socket. The answer to this predicament is light bulb grease. This is the primary use of dielectric grease.

It prevents rust from developing in electrical connectors/connections and ensures the free flow of electricity.

If you enclose your bulb tightly to the socket, the lack of ventilation speeds up the bulb’s burnout. Heat contributes greatly to this condition. Moisture also has a part in it as well.

To avoid this difficult situation of not prying out a stuck bulb from its socket, you need to use dielectric or light bulb grease the first time you thread a light bulb to its socket. And this is where bulb grease comes in handy.

Dielectric grease will protect light bulbs from water entry, prevent corrosion and extend their service lives. You need to learn how to use bulb grease because it is a way for you to save time and money.

How to Use Bulb Grease?

The rule of thumb is to use just a small amount of dielectric grease at the start wherever you want to apply it. Let’s assume that you will use it in the boots of the spark plugs.

Here’s what you need to do:

- Squeeze out a small amount of the grease from its tube or its packet.

- Coat this small amount of grease inside one of the spark plug boots.

- Don’t allow the grease to go down and reach the terminal inside the spark plug wire. If it does, your car will experience misfiring.

- Apply a small amount of grease in the thread of the spark plug as well.

The important thing to remember is to use just a small amount of dielectric grease wherever you want to apply it.

You can also use bulb grease on electrical connections. The grease will seal the connections properly and keep them from being corroded by water and air. Coating electrical connections with dielectric grease will prevent electric arcing as well.

Bulb grease is basically made of silicone material. Therefore, you should not use it on surfaces that are coated with plastics or silicone-based rubbers. The grease will break down these materials over time.

You should not apply dielectric grease directly on the mating surfaces of electrical connections or parts, such as sockets and pins.

Can You Use Bulb Grease in Headlights?

Dielectric grease is designed to seal the electrical connector so that moisture and water will not penetrate the electrical connection and corrode the pins. To that effect, you can call it headlight bulb grease.

But do you need to bulb grease your car’s headlights? It is not really necessary to do it because most headlights are built with waterproof housing inside.

But if you see any rust or corrosion developing on the headlight housing when you remove the bulb, it would be a good idea to clean the socket first and then apply a small amount of dielectric grease on it.

Uses of Dielectric Grease

Since bulb grease is silicone-based, it is, therefore, a non-conductive material. It is also non-curing, meaning it does not solidify or get hard over time. But if it is subjected to dirt and grime, it will accumulate debris over time.

The moment you squeeze it out of its tube or packet, you will notice its greasy consistency. It will remain greasy throughout its entire lifetime. It is just like any grease and will not get hard even for a long time. Being non-conductive, it can also act as an insulator and can be used as such.

Here are some of the effective uses of dielectric grease.

1. Anti-rust and Anti-corrosion Agent

Applying the right amount of dielectric grease on electrical connectors such as bulb sockets will prevent corrosion on the metal parts. The efficiency of electrical sockets will go down if rust or corrosion is present on their metal parts. It will cause the bulb not to light up when it is switched on.

Bare metal, if left unprotected, is subject to a chemical reaction when exposed to oxygen and air. It will undergo the process of oxidation. When an electrical socket is oxidized, it will reduce electricity flow because it is already oxidized. That means it is less conductive than it was before.

The reduced flow of electricity won’t be much of a problem if the socket’s oxidation is not that significant. However, if the socket’s oxidation is left unchecked and uncorrected, significant conductivity problems will arise in time.

In due time, the socket voltage will be reduced and cause the light bulb to work improperly. More serious electrical problems may arise, such as electrical sparks and short circuits.

2. Insulator to Prevent Electric Arcing

Dielectric grease can be used as an insulator. This concept is related to number 1. Electric arcing is manifested by electrical sparks. This is the more serious problem of oxidized or corroded electrical connectors and connections.

One effective way to prevent electric arcing in connectors and electrical connections is by using dielectric grease. It will act as an insulator to prevent arcing. The dielectric grease will reduce the voltage leak if a voltage spike comes from the power source.

3. Protective Water and Moisture Barrier

You can use bulb grease to create a secure electrical connection. The silicone material in the grease can effectively keep water and air from contacting the electrical connectors’ metal.

When air and water are prevented from getting in, corrosion and short circuits will no longer be a problem.

4. Lubricant of Rubber and Plastic Parts

You can use it to prolong the plastic and rubber parts of electrical connectors’ service lives. If you lubricate rubber and plastic fittings, you will also ensure that they will not fuse with the metal parts.

You can use dielectric grease to unstuck bulbs and electrical connectors and connections difficult to remove and take apart in this respect.

For example, lubricating spark plug threads with dielectric grease before putting them inside their boots will prevent them from fusing with their boots.

5. Sundry Applications

Bulb grease does not dissolve in liquid so you can use it in many ways. Here are some of the other ways you can use this beneficial grease:

- Insulate electrical panels, battery terminals, and circuit breakers

- Protect headlamp connectors

- Protect bulkhead connectors

- Insulate vehicle electrical wiring

- Protect ignition coil connectors

- Protect electrical sockets in the home

Conclusion: Bulb Grease

Bulb grease is good at preventing corrosion and rust on electrical sockets and electrical parts. It is dielectric grease that is typically made of silicone. When applied to electrical parts, it will improve electrical connections.

This dielectric grease can protect against moisture because it is waterproof. You can use it on electrical connections, tail lights, light bulbs, flood lamps, headlights, batteries, and many more.

How to apply bulb grease? Applying bulb grease is quite simple. The 5 steps to apply bulb grease are as follows:

- Remove the Electrical Part

- Clean the Electrical Part

- Scrape Off Tough Dirt

- Apply Bulb Grease

- Reassemble the Connector

Read next:

DRL Warning Light [What Does It Mean, Causes, and How to Fix]

![Check Engine Light On and Off Intermittently [Causes and Fixes] check engine light on and off](https://roadsumo.com/wp-content/uploads/2021/06/check-engine-light-on-and-off-150x150.jpg)

![Read more about the article Check Engine Light On and Off Intermittently [Causes and Fixes]](https://roadsumo.com/wp-content/uploads/2021/06/check-engine-light-on-and-off-300x200.jpg)