Piston return springs are an essential component of an engine’s valve train system. They are responsible for returning the valve to its closed position after it has been opened by the camshaft.

Without piston return springs, the valve would remain open, causing a loss of compression and potentially damaging the engine.

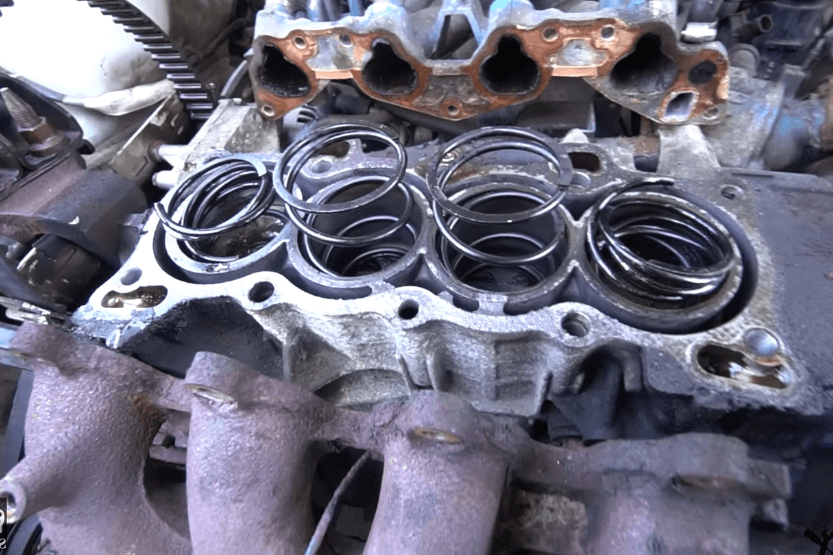

Piston return springs are typically made of high-quality steel and are designed to withstand the high temperatures and stresses of the engine. They come in a variety of sizes and spring rates, depending on the engine’s specifications.

It is important to choose the correct piston return spring for your engine to ensure proper valve operation and prevent engine damage.

Replacing piston return springs can be a challenging task, as it requires disassembling the engine’s valve train system. However, it is a necessary maintenance procedure that should be performed periodically to ensure the engine’s optimal performance.

In the following sections, we will explore the function of piston return springs, their importance in the engine’s valve train system, and the steps involved in replacing them.

What is the Use of Piston Return Spring?

Piston return springs are an essential component of the engine’s valve train. They are designed to return the piston to its original position after each stroke.

The spring rate of the piston return spring determines the force required to compress the spring and the force exerted by the spring to return the piston to its original position.

The main function of the piston return spring is to keep the piston in contact with the cam lobe, which ensures that the valve timing is correct. The spring rate of the piston return spring is critical, as it determines the speed at which the valve closes.

A spring rate that is too low will cause the valve to close too slowly, resulting in poor engine performance. Conversely, a spring rate that is too high will cause the valve to close too quickly, resulting in excessive wear on the valve and valve seat.

Piston return springs are also responsible for maintaining the correct tension on the timing chain or belt. The correct tension is necessary to prevent timing chain or belt slip, which can result in engine damage.

In summary, piston return springs are a critical component of the engine’s valve train. They ensure that the valve timing is correct, maintain the correct tension on the timing chain or belt, and prevent engine damage.

The spring rate of the piston return spring is critical and must be carefully selected to ensure proper engine performance.

How Do Return Springs Work?

Return springs are an essential component of an engine’s piston system. These springs are designed to help the piston return to its original position after it has been pushed down by the combustion process.

Without return springs, the piston would not be able to move back up, and the engine would not be able to function properly.

As per Car Info Hut (.com), return springs work by storing potential energy when the piston is pushed down. This energy is then released when the piston is released, and it helps to push the piston back up.

The energy is stored in the form of potential energy, which is converted into kinetic energy when the piston is released.

Return springs are typically made of high-quality materials to ensure that they are strong and durable. They are designed to withstand the high temperatures and pressures that are present in an engine’s combustion chamber.

The number of return springs needed depends on the number of cylinders in the engine. For example, a four-cylinder engine would require four return springs. It is essential to use high-quality return springs to reduce engine wear and maintain piston load for a smoother ride.

In summary, return springs are a crucial component of an engine’s piston system. They work by storing potential energy when the piston is pushed down and releasing it to help push the piston back up.

It is essential to use high-quality return springs to ensure that the engine functions properly and to reduce engine wear.

Common Problems and Symptoms

Piston return springs are a critical component of an engine’s internal system. Over time, they can become worn or damaged, leading to a variety of issues.

Here are some of the most common problems and symptoms associated with faulty piston return springs:

Rough Engine Performance

One of the most noticeable symptoms of a faulty piston return spring is a rough engine performance. This can manifest as engine misfires, hesitation, or a lack of power.

It’s important to note that rough engine performance can also be caused by other issues, such as faulty spark plugs or a clogged fuel injector. Therefore, it’s essential to have a professional mechanic diagnose the issue to determine the exact cause.

Faulty Piston Rings

Faulty piston return springs can also cause problems with the piston rings. Piston rings are responsible for sealing the combustion chamber, preventing oil from leaking into the cylinders.

If the piston return springs are worn or damaged, they can cause the piston rings to wear out faster than usual. This can lead to engine oil consumption, reduced engine power, and increased emissions.

Check Engine Light

A faulty piston return spring can trigger the check engine light on the dashboard. The check engine light can indicate a wide range of issues, so it’s important to have the engine diagnosed by a professional mechanic to determine the exact cause.

If the check engine light is caused by a faulty piston return spring, the mechanic will need to replace the spring to resolve the issue.

In summary, faulty piston return springs can cause a variety of problems with an engine’s performance. If you notice any of the symptoms mentioned above, it’s essential to have the issue diagnosed by a professional mechanic.

By addressing the issue promptly, you can prevent further damage to your engine and ensure that it runs smoothly for years to come.

Replacement and Installation

When it comes to replacing and installing piston return springs, there are a few important steps to follow to ensure a successful job.

First, the old springs need to be removed from the engine. This can be done by carefully loosening the bolts that hold the springs in place and then gently removing them from the engine.

Once the old springs have been removed, it is time to install the new ones. Before installing the new springs, it is important to make sure that they are the correct size and type for the engine. This can be done by consulting the vehicle’s owner’s manual or by speaking with a trusted mechanic.

To install the new springs, the mechanic should carefully place them into the engine and secure them in place with the bolts. It is important to make sure that the bolts are tightened to the correct torque specifications to ensure that the springs are properly secured.

During the installation process, it is also important to make sure that all other components of the engine are in good working order. This includes checking the head gasket and other critical engine components to ensure that they are in good condition and working properly.

When replacing and installing piston return springs, it is important to have the right tools on hand. This may include a torque wrench, socket set, and other specialized tools. It is also important to follow all safety guidelines and to work carefully to avoid damaging the engine or other components.

In summary, replacing and installing piston return springs is an important maintenance task that can help keep a vehicle running smoothly. By following the proper steps and using the right tools, this task can be completed safely and efficiently.

Choosing the Right Piston Return Spring

When it comes to choosing the right piston return spring, there are a few factors that need to be considered. These factors include the type of engine, the horsepower, and the intended use of the vehicle.

One of the first things to consider is the spring rate. The spring rate is the amount of force required to compress the spring one inch. The higher the spring rate, the stiffer the spring. A stiffer spring will provide more support and stability, but it can also make the ride harsher.

Another important factor to consider is the warranty. It is recommended to choose piston return springs with a good warranty, preferably 100K miles. This ensures that the springs are of high quality and will last for a long time.

When looking for high-quality rings, it is important to consider the material. High-grade stainless steel is a good material choice as it increases temperature resistance. Additionally, spring materials experience different effects from extreme temperatures, depending on the material.

Reviews from other customers can also be helpful when choosing the right piston return spring. Reading reviews can provide insight into the durability and performance of the springs.

Lastly, when purchasing piston return springs, it is important to make sure that they are compatible with the specific make and model of the engine. This ensures that the springs will fit properly and function as intended.

So, coming at you as a mechanic who’s been at it for a while, here’s the deal: picking the right piston return spring is a big deal. It’s like a make-it-or-break-it kind of thing for your engine’s performance and how long it keeps humming.

Now, the secret sauce? Think about stuff like spring rate, warranty, what it’s made of, what others are saying, and whether it’ll play nice with your setup. Nail down these details, and you’re all set to make the smart choice for the best piston return spring that suits your needs.

To Summarize

Piston return springs are an important component of an engine’s valve train system. They ensure that the valve closes properly after the combustion process has occurred, preventing significant damage to the engine over time.

Piston return springs work by storing energy and releasing it when needed. They are typically made of a type of torsion spring and are wound up when the piston is pushed down.

When the hydraulic pressure is released, the spring stack forces the piston back to its original position, resulting in consistently smooth shifting.

When replacing piston return springs, it is important to purchase high-quality rings that will reduce engine wear by pushing the piston downward with each engine revolution. The number of cylinders in the engine determines how many piston return springs to buy.

Overall, piston return springs are necessary for cars to work perfectly and should be maintained and replaced as needed to ensure proper engine function.

![RockAuto Return Policy [Return and Refunds Explained] rockauto return policy](https://roadsumo.com/wp-content/uploads/2022/01/RockAuto-return-policy-150x150.jpg)

![Costco Tire Warranty [How It Works and What It Covers] Costco Tire warranty](https://roadsumo.com/wp-content/uploads/2021/05/Costco-tire-warranty-150x150.png)

![Walmart Tire Warranty [How It Works and What It Covers] Walmart Tire Warranty](https://roadsumo.com/wp-content/uploads/2021/12/Walmart-tire-warranty-150x150.jpg)